As the global population continues to surge, the demand for food and industrial products is driving an urgent need for sustainable solutions. Ammonia, a critical component in fertilizers and various industrial applications, plays a vital role in enhancing agricultural productivity and supporting economic growth. However, traditional ammonia production methods, primarily reliant on fossil fuels, are responsible for significant greenhouse gas emissions, contributing to climate change and environmental degradation.

Enter green hydrogen—a revolutionary alternative that promises to transform ammonia production into a cleaner, more sustainable process. By harnessing renewable energy to produce hydrogen through electrolysis, the agricultural and industrial sectors can significantly reduce their carbon footprint. This article explores how the integration of green hydrogen into ammonia production not only addresses environmental concerns but also paves the way for a more sustainable future in food security and industrial innovation.

Understanding Ammonia Production

A. The Haber-Bosch Process: An Overview

At the heart of ammonia production lies the Haber-Bosch process, a groundbreaking chemical reaction developed in the early 20th century. This process combines nitrogen from the air with hydrogen, typically derived from natural gas, under high temperature and pressure to produce ammonia. While revolutionary for its time, the Haber-Bosch process is energy-intensive and heavily dependent on fossil fuels, contributing to approximately 1.8% of global greenhouse gas emissions. Despite these challenges, the process remains the dominant method for ammonia synthesis due to its efficiency and scalability.

B. Importance of Ammonia in Fertilizers and Industrial Applications

Ammonia is an indispensable resource in agriculture, serving as a key ingredient in nitrogen-based fertilizers that enhance crop yields and food production. It is estimated that nearly 80% of the ammonia produced globally is used for fertilizers, directly impacting food security for billions. Additionally, ammonia plays a crucial role in various industrial applications, including the production of plastics, explosives, and cleaning agents. As the world grapples with the dual challenges of climate change and food scarcity, the demand for sustainable ammonia production has never been more critical.

C. Current Global Ammonia Production Statistics

According to recent statistics, global ammonia production exceeds 180 million metric tons annually, with significant contributions from countries like China, India, and the United States. The reliance on fossil fuels for this production raises concerns about environmental sustainability and highlights the urgent need for a transition to greener alternatives. As the world seeks to decarbonize its economy, innovative solutions such as green hydrogen offer a promising path forward.

The Case for Green Hydrogen

A. Definition and Production of Green Hydrogen

Green hydrogen is produced through the electrolysis of water, a process that uses renewable energy sources—such as wind, solar, or hydropower—to split water molecules into hydrogen and oxygen. Unlike traditional hydrogen production methods, which often involve natural gas reforming and result in significant carbon emissions, green hydrogen offers a clean and sustainable alternative. As technology advances and the cost of renewable energy continues to decline, the feasibility of green hydrogen production is rapidly increasing.

B. Environmental Benefits of Using Green Hydrogen

The environmental benefits of green hydrogen are substantial. By substituting fossil fuel-derived hydrogen in the ammonia production process, companies can significantly reduce their greenhouse gas emissions. This shift not only contributes to global climate goals but also enhances sustainability by utilizing abundant renewable resources. As countries aim to meet their net-zero targets, green hydrogen emerges as a pivotal player in achieving a cleaner and more sustainable future.

Integrating Green Hydrogen into Ammonia Production

A. Modifying the Haber-Bosch Process to Utilize Green Hydrogen

Integrating green hydrogen into the Haber-Bosch process requires modifications to the existing technology. By replacing conventional hydrogen sources with green hydrogen, manufacturers can produce ammonia with a significantly lower carbon footprint. Researchers and engineers are actively exploring ways to optimize this integration, making it more efficient and cost-effective.

B. Innovations and Technologies in Ammonia Synthesis with Green Hydrogen

Recent innovations in ammonia synthesis technology, such as the development of solid oxide electrolysis cells (SOECs) and novel catalysts, are enhancing the efficiency of using green hydrogen. These advancements are crucial for scaling up green ammonia production and making it commercially viable. The ongoing research in this field is promising, and the potential for breakthroughs could accelerate the transition to sustainable ammonia production.

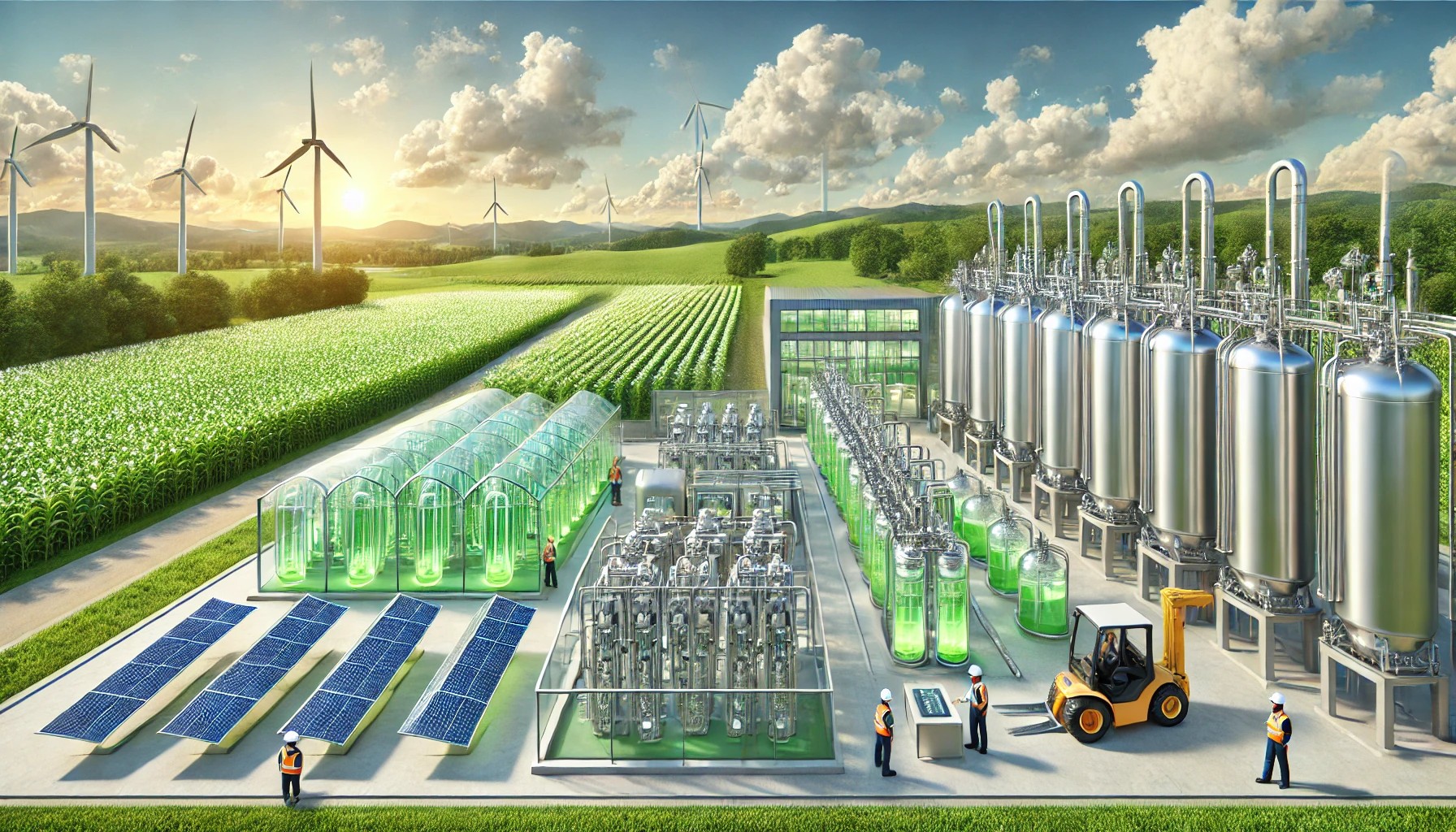

C. Case Studies of Successful Green Ammonia Production Plants

Several pilot projects and commercial plants worldwide are already demonstrating the viability of green ammonia production. Notable examples include the world’s first green ammonia plant in Norway, which utilizes hydropower for electrolysis, and a new facility in Australia that aims to export green ammonia to international markets. These case studies highlight the progress being made in the field and serve as models for future developments.

Economic Implications

A. Cost Analysis: Green Hydrogen vs. Traditional Methods

While the initial investment for green hydrogen production can be high, ongoing advancements in technology and the decreasing costs of renewable energy sources are making it increasingly competitive with traditional methods. As economies of scale are achieved, the cost of producing green ammonia is expected to decline, making it an attractive option for the agricultural and industrial sectors.

B. Potential for Job Creation in the Green Hydrogen Sector

The transition to green hydrogen not only addresses environmental concerns but also presents significant economic opportunities. As the sector grows, it is anticipated to create a wide range of jobs in manufacturing, installation, maintenance, and research. This shift could revitalize local economies and contribute to a more sustainable workforce.

C. Long-term Economic Benefits for the Agricultural and Industrial Sectors

Investing in green hydrogen technology has the potential to yield long-term economic benefits, including increased energy security and reduced dependence on fossil fuels. By adopting sustainable practices, businesses can enhance their competitiveness and resilience in an increasingly eco-conscious market. The agricultural sector, in particular, stands to gain from the availability of affordable, green ammonia fertilizers, promoting sustainable food production practices.

Challenges and Solutions

A. Technological Hurdles in Green Hydrogen Production and Storage

Despite its potential, several technological challenges remain in the production and storage of green hydrogen. Efficient electrolysis technology, storage solutions, and transportation infrastructure need further development to ensure the scalability of green hydrogen production.

B. Infrastructure Requirements for Scaling Green Ammonia Production

The transition to green ammonia production will require significant investments in infrastructure, including electrolysis facilities, ammonia synthesis plants, and transportation networks. Collaborative efforts between governments, industries, and research institutions will be crucial in building this necessary infrastructure.

C. Policy and Regulatory Frameworks to Support the Transition

Effective policy and regulatory frameworks are essential to promote the adoption of green hydrogen technologies. Governments can incentivize investment in renewable energy and green hydrogen projects, creating an environment that fosters innovation and supports the transition to sustainable ammonia production.

Future Perspectives

A. Potential Advancements in Technology and Research

As research in green hydrogen and ammonia synthesis continues to advance, we can expect significant breakthroughs that will enhance efficiency and reduce costs. Investments in research and development will be pivotal in unlocking the full potential of green hydrogen as a cornerstone of sustainable ammonia production.

B. Role of Green Ammonia in Achieving Global Climate Goals

Green ammonia has the potential to play a vital role in global climate strategies. By replacing traditional ammonia production methods with sustainable alternatives, countries can make significant strides toward achieving their net-zero targets and fostering a more sustainable agricultural sector.

C. Collaborations Between Governments, Industries, and Researchers

Collaboration will be key in driving the transition to green ammonia production. Partnerships between governments, private sector stakeholders, and research institutions can facilitate knowledge sharing, resource allocation, and technology development, ultimately accelerating the shift toward a sustainable future.

Conclusion

The need for sustainable ammonia production has never been more urgent. By revolutionizing the traditional processes with green hydrogen, we can address environmental concerns while supporting global food security and industrial growth. Stakeholders must come together to invest in green hydrogen technologies, fostering innovation and collaboration to pave the way for a cleaner, more sustainable future in ammonia production.

Frequently Asked Questions (FAQs)

1. What is green hydrogen?

Green hydrogen is hydrogen produced through the electrolysis of water using renewable energy sources, such as wind, solar, or hydropower. This process generates hydrogen without releasing greenhouse gases, making it a sustainable alternative to hydrogen produced from fossil fuels.

2. How does green hydrogen benefit ammonia production?

By using green hydrogen in the ammonia production process, manufacturers can significantly reduce their carbon footprint. This shift allows for the production of ammonia in a more environmentally friendly manner, aligning with global efforts to combat climate change.

3. What are the main applications of ammonia?

Ammonia is primarily used in the production of fertilizers, which are essential for enhancing crop yields and ensuring food security. Additionally, ammonia has various industrial applications, including the manufacturing of plastics, explosives, and cleaning products.

4. What are the challenges in implementing green hydrogen technology?

Key challenges include technological hurdles in hydrogen production and storage, the need for significant infrastructure investments, and the development of supportive policy and regulatory frameworks to facilitate the transition to green ammonia production.

5. How can green ammonia contribute to global climate goals?

By replacing traditional ammonia production methods with green hydrogen, countries can significantly reduce greenhouse gas emissions. This transition supports global efforts to achieve net-zero targets and promotes sustainable agricultural practices.

6. Are there any successful examples of green ammonia production plants?

Yes, several pilot projects and commercial plants are successfully producing green ammonia. Notable examples include the world’s first green ammonia plant in Norway and a new facility in Australia, which aims to export green ammonia to international markets.

7. What is the potential for job creation in the green hydrogen sector?

The transition to green hydrogen technologies is expected to create numerous job opportunities in various fields, including manufacturing, installation, maintenance, and research, thus revitalizing local economies and fostering a sustainable workforce.

8. How does the cost of green hydrogen compare to traditional methods?

While initial investments in green hydrogen production can be high, ongoing advancements in technology and decreasing renewable energy costs are making green hydrogen increasingly competitive with traditional methods. As economies of scale are achieved, the cost of green ammonia production is expected to decline further.

9. What role can governments play in promoting green hydrogen and ammonia production?

Governments can incentivize investment in renewable energy and green hydrogen projects, create supportive regulatory frameworks, and foster collaborations between industry and research institutions to drive innovation and accelerate the transition to sustainable ammonia production.