The steel industry, a cornerstone of global infrastructure, is also one of the largest industrial contributors to greenhouse gas emissions. With rising environmental concerns and mounting pressure for industries to reduce their carbon footprints, the need for transformative solutions has never been more urgent. Among the most promising solutions on the horizon is hydrogen—a clean and versatile energy source that could revolutionize the way steel is made and pave the way for a sustainable future.

The steel industry accounts for nearly 8% of global carbon dioxide emissions, primarily due to the reliance on coal and coke in traditional blast furnace processes. As the world intensifies its efforts to combat climate change, heavy industries like steel are facing increasing pressure to reduce their environmental impact. Decarbonizing such a resource-intensive sector is not only essential for meeting global climate goals but also for advancing towards a net-zero economy. Amidst this urgency, hydrogen emerges as a promising solution. By replacing carbon-intensive processes with hydrogen, the steel industry has the potential to dramatically lower its emissions and become a key player in the transition to a cleaner, greener future. This article explores hydrogen’s transformative role in decarbonizing steel production and its potential to reshape the industry.

1. The Steel Industry’s Carbon Footprint

The steel industry is one of the most energy-intensive sectors, accounting for approximately 8% of global CO2 emissions. This is largely due to the traditional methods used in steel production, where coal and coke are essential in the reduction of iron ore. Specifically, the blast furnace process, the most common method for producing steel, generates significant amounts of carbon dioxide. In this process, iron ore is reduced using coke, which releases large quantities of CO2. The Basic Oxygen Furnace (BOF) method, often used in tandem with blast furnaces, further contributes to emissions by burning coke to convert iron into steel. Combined, these processes contribute more than 70% of emissions in steel production, making the sector one of the most challenging to decarbonize. Efforts to reduce emissions are compounded by the energy demands and the high temperatures required to process iron ore—factors that have long made the steel industry a “hard-to-abate” sector.

2. Hydrogen as a Clean Alternative

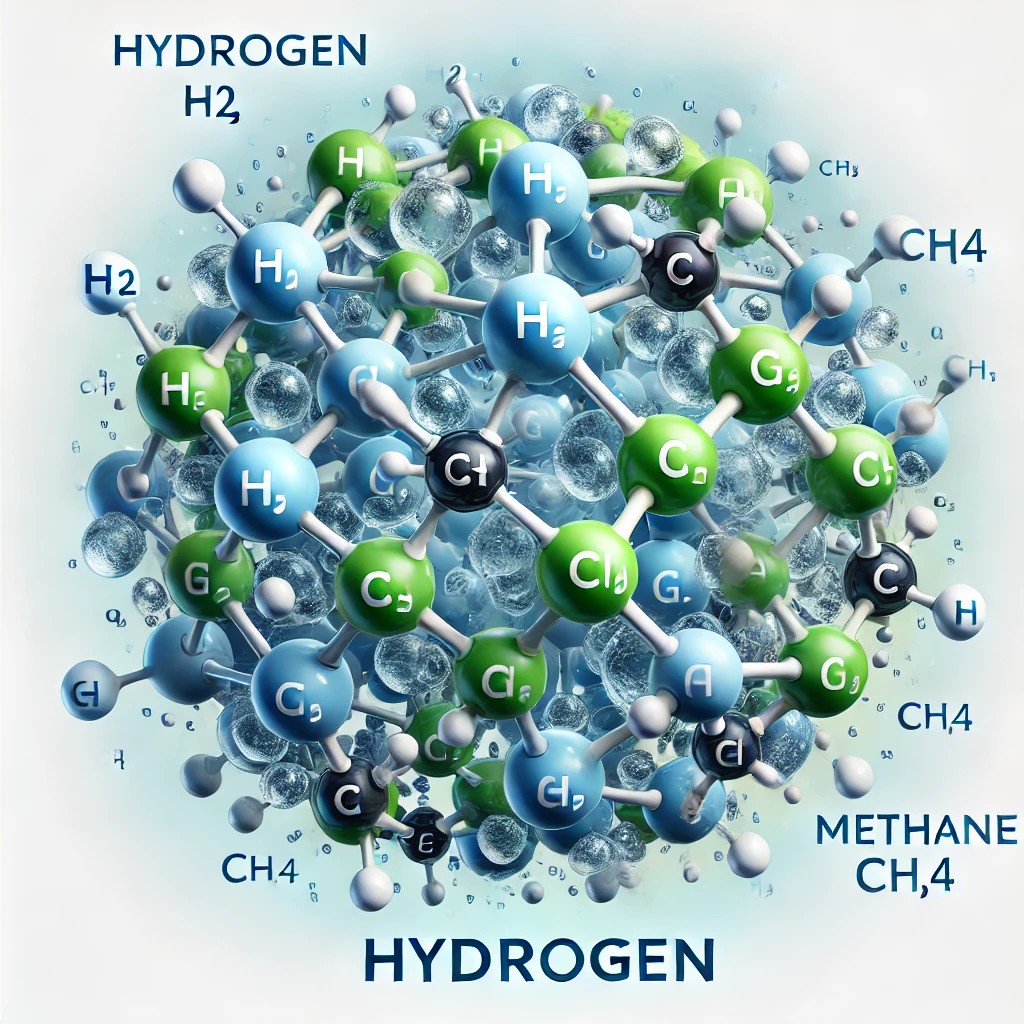

Hydrogen offers a promising solution for decarbonizing steel production by replacing coal and coke with a clean alternative for reducing iron ore. Unlike traditional methods, which produce CO2 as a byproduct, hydrogen-based reduction emits only water vapor. In this process, hydrogen gas reacts with iron ore to produce iron and water, eliminating the carbon emissions typically associated with the reduction of iron. There are three types of hydrogen: gray hydrogen, produced from natural gas through a process that emits CO2; blue hydrogen, which is also derived from natural gas but incorporates carbon capture and storage (CCS) to reduce emissions; and green hydrogen, which is generated by splitting water into hydrogen and oxygen using renewable electricity. Green hydrogen is the most sustainable option for steel production, as it generates zero emissions, making it particularly relevant for industries aiming for net-zero targets. Hydrogen’s role in steelmaking extends beyond just emissions reduction—it also offers the potential for a cleaner and more energy-efficient alternative to current practices, aligning the steel industry with global decarbonization goals.

3. Hydrogen-Based Steelmaking Technologies

Among the promising technologies for hydrogen-based steelmaking is Direct Reduced Iron (DRI). In a hydrogen-based DRI process, hydrogen gas is used instead of coke to reduce iron ore, creating sponge iron and water vapor rather than CO2. This technology is gaining momentum as a clean alternative to traditional methods, particularly in regions where hydrogen production can be sourced from renewable energy. Another approach is the integration of hydrogen into Electric Arc Furnaces (EAF), where hydrogen is mixed with electricity to melt scrap steel, reducing its carbon footprint. EAFs are already considered more sustainable than blast furnaces, and hydrogen can further reduce their environmental impact. Several innovative projects and pilot programs are currently underway to scale these technologies. In Sweden, the HYBRIT project (Hydrogen Breakthrough Ironmaking Technology) aims to demonstrate the feasibility of producing fossil-free steel using hydrogen. Likewise, H2 Green Steel, a startup backed by major investors, is working on building a hydrogen-based steel plant in Sweden, with the goal of reducing CO2 emissions by up to 5 million tons annually. These initiatives are a critical step toward transforming the steel industry and proving that hydrogen can be an effective tool for large-scale decarbonization.

4. Challenges in Scaling Hydrogen for Steel Production

Despite its potential, scaling hydrogen-based steel production presents several challenges. First, the infrastructure required for hydrogen storage and transport is still in its infancy. Hydrogen has a low energy density, making it difficult to store and move in large quantities without costly, specialized tanks and pipelines. Additionally, producing green hydrogen at scale remains a challenge due to the high cost of renewable electricity and electrolysis equipment. Current costs for green hydrogen are significantly higher than those for coal-based steel production, making it economically uncompetitive without subsidies or strong policy incentives. The availability of renewable energy is another critical factor—producing hydrogen via electrolysis requires vast amounts of clean electricity, which may not be readily available in all regions. These technological and economic hurdles must be addressed to make hydrogen a viable and widespread solution for the steel industry.

5. Environmental and Economic Benefits

The environmental benefits of hydrogen in steelmaking are clear—by eliminating CO2 emissions from traditional steel production methods, hydrogen could significantly reduce the sector’s contribution to global warming. In addition to cutting CO2 emissions, hydrogen use in steel production can also reduce other pollutants, such as sulfur dioxide and nitrogen oxides, that are typically released during the combustion of coal. On the economic side, the transition to hydrogen steelmaking offers opportunities for new business models and green jobs in sectors like hydrogen production, renewable energy, and carbon capture technology. Long-term, hydrogen-based steel production could become more cost-competitive as technology improves and renewable energy becomes cheaper. This transition could also foster innovation and collaboration across industries, leading to a more sustainable and diversified economy.

6. Policy Support and Global Initiatives

Governments around the world are recognizing the importance of hydrogen in decarbonizing heavy industries. Policy frameworks like the European Union’s Green Deal and national hydrogen strategies are providing the necessary incentives and regulations to foster hydrogen adoption. Financial support, such as subsidies for green hydrogen production and tax incentives for low-carbon technologies, are critical in reducing the high initial costs of hydrogen-based steel production. Additionally, international collaborations, like the Clean Hydrogen Partnership in Europe, aim to accelerate research and investment in hydrogen technologies. Key players in the steel industry, including major manufacturers such as SSAB, ArcelorMittal, and Thyssenkrupp, are also making substantial investments to explore hydrogen-based solutions, further demonstrating the growing commitment to transitioning the sector.

7. Future Outlook

As hydrogen technology matures, it is expected that by 2030, several large-scale hydrogen-based steel plants will be operational, particularly in regions with abundant renewable energy resources. The EU, for example, aims to produce 10 million tons of renewable hydrogen annually by 2030, with steel production being a major target sector. By 2040, hydrogen could become the standard for steelmaking in countries committed to achieving net-zero emissions. Key milestones will include improved hydrogen production technologies, more efficient storage and transport solutions, and a reduction in the cost of green hydrogen. These advancements, along with continued policy support and investment, will help shape the steel industry’s future, making hydrogen a cornerstone of a cleaner, more sustainable global economy.

Conclusion

Hydrogen has the potential to revolutionize the steel industry, offering a pathway to significant emissions reductions and a more sustainable future. As technology advances and policies align to support this transformation, hydrogen-based steelmaking could become the norm, rather than the exception. However, achieving this vision will require continued investment in research, infrastructure, and policy frameworks to overcome current challenges. The future of the steel industry lies in collaboration between governments, businesses, and researchers to harness hydrogen’s full potential and lead the way toward a decarbonized world.

Frequently Asked Questions (FAQs)

1. How does hydrogen reduce emissions in steel production?

Hydrogen reduces emissions in steel production by replacing coke (a carbon-rich material) with hydrogen gas to reduce iron ore. Instead of producing CO2, hydrogen produces water vapor as the byproduct, which significantly reduces the carbon footprint of the steelmaking process.

2. What types of hydrogen are used in steel production?

There are three primary types of hydrogen:

- Gray hydrogen is produced from natural gas and results in CO2 emissions.

- Blue hydrogen is also produced from natural gas, but carbon capture and storage (CCS) are used to reduce emissions.

- Green hydrogen is produced through electrolysis using renewable energy sources like wind or solar, resulting in zero emissions and is the most sustainable option for steelmaking.

3. Is hydrogen-based steel production more expensive than traditional methods?

Currently, hydrogen-based steel production is more expensive than traditional coal-based methods. This is due to the high costs of producing green hydrogen and the need for specialized infrastructure. However, as renewable energy prices decrease and technology advances, the cost of hydrogen is expected to become more competitive in the coming years.

4. What are some real-world examples of hydrogen in steelmaking?

Notable projects include:

- HYBRIT in Sweden, which aims to eliminate fossil fuels from steel production by using hydrogen for iron ore reduction.

- H2 Green Steel, also in Sweden, is building a large-scale hydrogen-based steel plant to reduce CO2 emissions by up to 5 million tons annually.

5. Can hydrogen completely replace coal in steelmaking?

Hydrogen has the potential to replace coal in steel production, particularly in processes like Direct Reduced Iron (DRI). However, widespread adoption faces challenges such as cost, infrastructure, and energy availability. As technology develops and becomes more scalable, hydrogen could become the primary material for steel production.

6. What are the environmental benefits of hydrogen in steelmaking?

The environmental benefits of hydrogen in steelmaking include a drastic reduction in CO2 emissions, which are typically a major byproduct of coal-based methods. Hydrogen also reduces other harmful pollutants such as sulfur dioxide and nitrogen oxides, contributing to cleaner air and a healthier environment.

7. How can governments support hydrogen adoption in the steel industry?

Governments can support hydrogen adoption by providing subsidies and financial incentives for green hydrogen production, investing in hydrogen infrastructure, and creating policies that encourage the transition to low-carbon steelmaking. The EU’s Green Deal and national hydrogen roadmaps are examples of frameworks that support such initiatives.

8. When will hydrogen-based steel production become mainstream?

The mainstream adoption of hydrogen in steel production is expected to begin by 2030, with several large-scale hydrogen-based plants becoming operational. However, achieving widespread use will depend on overcoming technological, economic, and logistical challenges. By 2040, hydrogen could be a dominant solution for decarbonizing the steel industry, especially in regions with abundant renewable energy resources.

9. What is Direct Reduced Iron (DRI) and how does hydrogen play a role?

Direct Reduced Iron (DRI) is a method of making iron without using a blast furnace. In hydrogen-based DRI, hydrogen gas is used to reduce iron ore, producing iron and water vapor instead of CO2. This method is central to hydrogen’s role in transforming steelmaking into a cleaner process.

10. What are the challenges in scaling hydrogen-based steel production?

Key challenges include:

- Infrastructure: Building the necessary storage, transport, and distribution networks for hydrogen.

- Cost: Producing green hydrogen is currently expensive, and scaling it to meet global steel demands will require significant investment.

- Energy supply: Large-scale hydrogen production requires vast amounts of renewable electricity, which may not be available in all regions.